After performing quality control, Test-it-off takes care of sorting PCBs based on the specified parameters. The robotic arm removes the PCB from the ICT tester and moves it to the correct location depending on the type of defect. The verified pieces are stored in the storage area designated for dispatch and the DMX code is read or the production label is added to guarantee full traceability.

The PCB storage method is based on the customs and logistics strategy of each customer. Test-it-off adapts without difficulty. When designing the final solution, we take into account the requirement for the period during which Test-it-off must function autonomously. A typical requirement is the system’s ability to work independently at least for several hours.

Based on the identified requirements, we propose a way to create a sufficient supply of PCBs. Reaching a sufficient stock is usually realized by chaining the basic container for storing PCBs (e.g., KLT box) on the conveyor or gravity hopper.

Test-it-off is a versatile platform regarding the support of different ways of storing products. You can select any of the following before and after testing:

Pallets are a common method for storing printed circuit boards. This option poses no problem for Test-it-off and AUBO cobot. Depending on the storage angle and the size of the gaps between the individual PCBs, an attachment with vacuum suction cups or a fine two-finger gripper can be selected for handling.

Do you use CAB magazines in your production process and would you appreciate testing PCBs directly from them? Test-it-off is ready for this option. The AUBO cobot grips the board and slides it out of the magazine with the help of a two-finger gripper. PCBs can be placed back in the same way. Alternatively, for verified PCBs, choose storage directly in the KLT box and prepare the production for dispatch.

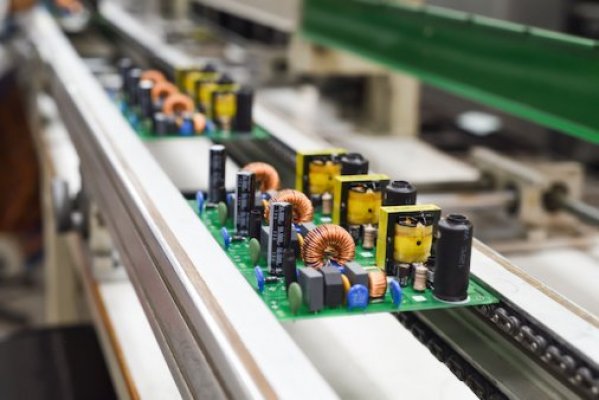

Due to the system’s high variability, the tested PCBs can be taken directly from the production line. Therefore, it is not necessary to use only static product locations. To compare production speed and test cycle length, Test-it-off offers the possibility of intelligent distribution of PCBs between multiple ICT testers.

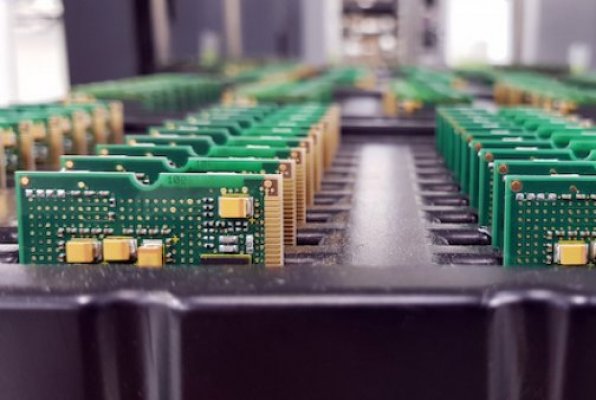

Test-it-off can easily handle it even if the task is to test bulk PCBs in a KLT box. Although in such a case the individual PCB layers are often separated by horizontal interleaving, Test-it-off can function reliably for hours during testing. For example, this option is useful when it is necessary to check the claimed batches of PCBs directly from the shipping box.